Difference between fire-resistant cables and flame-retardant cables

Publication Time:

2020-01-05

Based on methods such as improving the fire-resistant layer manufacturing process and increasing the fire-resistant layer, Class A fire-resistant cables were developed, which can withstand burning for at least 90 minutes in flames at 950℃-1000℃ and under rated voltage without the cable being punctured (i.e., the 3A fuse does not blow).

I. Fire-resistant cables

Based on improvements in the manufacturing process of the fire-resistant layer and the addition of a fire-resistant layer, Class A fire-resistant cables have been developed. They can withstand burning for at least 90 minutes at 950℃~1000℃ under rated voltage without being punctured (i.e., the 3A fuse does not blow).

II. Flame-retardant cables

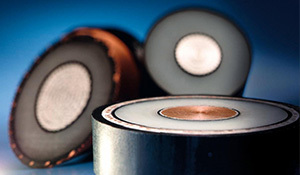

Flame-retardant cables are a superior type of fire-resistant cable. They are made of copper core, copper sheath, and magnesium oxide insulation material, abbreviated as MI (minerally insulated cables).

This cable is entirely composed of inorganic materials for the fire-resistant layer, while the fire-resistant layer of ordinary fire-resistant cables is a composite of inorganic and general organic materials. Therefore, MI cables have better fire resistance than ordinary fire-resistant cables and will not decompose and produce corrosive gases due to combustion.

MI cables have good fire-resistant properties and can work continuously at high temperatures of 250℃. They also feature explosion-proof, strong corrosion resistance, large current carrying capacity, radiation resistance, high mechanical strength, small size, light weight, long lifespan, and smokeless characteristics.

However, they are expensive, complex in manufacturing, and difficult to install. In places with high fire resistance requirements and acceptable economy, such as oil filling areas, important wooden public buildings, and high-temperature locations, this type of fire-resistant cable can be used.

Note: Fire-resistant cables can maintain normal power supply for a period of time during a fire, while flame-retardant cables do not have this characteristic.

III. Matters needing attention during design and application

1. When fire-resistant cables are used in cable tunnels, cable layers with dense cables, or flammable places near oil pipes and oil depots, Class A fire-resistant cables should be used first. Except for the above situations and when the number of cables is small, Class B fire-resistant cables can be used.

2. Fire-resistant cables are mostly used for emergency power supply circuits and are required to work normally during a fire. Since the ambient temperature rises sharply during a fire, to ensure the transmission capacity of the line and reduce the voltage drop, for circuits with longer power supply lines and strictly limited allowable voltage drop, the cross-section of the fire-resistant cable should be increased by at least one level.

3. Fire-resistant cables cannot be used as high-temperature cables.

4. To reduce the failure rate of cable joints in fire accidents, the number of joints should be minimized during installation to ensure that the lines can work normally during a fire. If branch wiring is needed, the joints should be fireproofed.

Recommended News

2024 Social Responsibility Report

2025-03-31

2023 Social Responsibility Report

2024-11-17

2022 Social Responsibility Report

2024-11-17

Youhui Cable Co., Ltd.

Service Hotline:

Email:

youhuixianlan@yeah.net

Production Base:

Jiajiakou Township, Huang'erying Village, Tai'an Road, Jia 6, Ningjin County, Hebei Province