How to truly distinguish the quality of cables and wires

Publication Time:

2020-01-03

Tampering with the cable length might be harder to detect because customers generally do not have equipment to actually measure the length. Similarly, using the weight measurement method can determine if the cable has the full length. Alternatively, having the factory print meter marks during production is also a good method. However, it is important to note that wires with a diameter smaller than 5mm cannot have meter marks printed on them.

It may be more difficult to detect manipulation of the meterage of the cable, as customers generally do not have the equipment to actually measure the length. Similarly, using a weighing method can determine if the cable is of sufficient length. Alternatively, having the factory print meter markings is also a good method, but it should be noted that meter markings cannot be printed on wires with a diameter less than 5mm.

Sufficient copper is a precious metal. If the copper diameter is slightly reduced, a significant amount of raw material cost can be saved. In this case, a micrometer should be used to measure the copper wire diameter. If a micrometer is not available, a simpler method is to weigh the entire roll of wire to see if it is much lighter than high-quality cables. Alternatively, the nominal weight provided by the factory can be referenced. Some factories provide lower nominal weights, which naturally cannot guarantee product quality.

How to distinguish the internal quality of wires and cables:

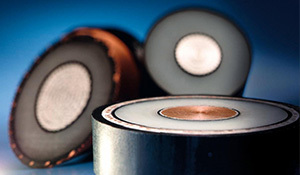

High-quality cables use high-purity oxygen-free copper. The copper core has a bright luster, while inferior copper wires have a duller surface.

Extrusion Machine

Plastic: High-quality virgin plastic is used, with good bending performance. Bending the cable will not produce texture. Inferior recycled plastic will show obvious texture after several bends and will break after multiple bends.

Cable Equipment

Auxiliary Materials: To ensure the roundness of the cable, fillers are added to the cores of multi-core cables, and the sheath thickness is made thicker. If the cable in hand is not very round, it indicates that very little filler has been added, and the sheath is thin.

Cable Equipment

Stranding: Multiple copper wires are stranded during production to improve the tensile strength, roundness, electrical performance, and tightness with the insulation layer of the copper core. However, since stranding increases copper usage, many factories omit this step. The method of identification is to dissect the cable core and see if the copper wires inside are regularly twisted together.

Weaving: For cables with a copper mesh weaving layer, the weaving layer accounts for a large part of the cable's raw material cost. The coverage rate of the weaving layer directly affects the cable's electrical performance. At the same time, a tight weaving layer can increase the cable's strength and reduce the decline in electrical performance when the cable is bent. Therefore, observing whether the weaving layer has high coverage and is evenly and finely woven is an important means of distinguishing between superior and inferior cables.

Recommended News

2024 Social Responsibility Report

2025-03-31

2023 Social Responsibility Report

2024-11-17

2022 Social Responsibility Report

2024-11-17

Youhui Cable Co., Ltd.

Service Hotline:

Email:

youhuixianlan@yeah.net

Production Base:

Jiajiakou Township, Huang'erying Village, Tai'an Road, Jia 6, Ningjin County, Hebei Province