Analysis of the real differences between national standard cables and non-standard cables

Publication Time:

2020-01-09

Calculate the cost based on the weight of copper. It worked at first, but the national standard ignored a problem: your copper is oxygen-free rod, while non-standard copper is not. When the weight of scrap copper and oxygen-free rod is the same, the price difference between scrap copper and oxygen-free rod is 10%. Therefore, national standard cables have been heavily promoted.

A sensitive topic familiar to cable industry professionals for years: it's too difficult to sell cables that meet national standards. Everyone claims their cables meet national standards, even non-standard cables are claimed as such, giving them a pricing advantage. This has left cable market professionals quite helpless.

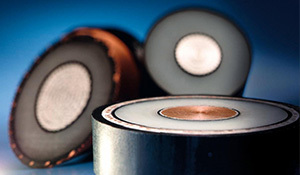

What are the real differences between national standard cables and non-standard cables? Let's take a closer look at the following points:

1. Calculating cost based on copper weight. Initially, this was effective. However, those producing national standard cables overlooked one issue: their copper is oxygen-free rod, while non-standard copper is not. When the weight of scrap copper and oxygen-free rod is the same, the price difference between them is 10%. Therefore, the extensive promotion of national standard cables failed, with a price difference of at least 10% between national standard and non-standard cables.

2. Cutting corners on auxiliary materials. The government has increased inspections on resistance and regular products. Non-standard cables are now cutting corners on auxiliary materials. If copper accounts for 70% of the cable cost, auxiliary materials account for about 20%. A slight reduction in the quality of these materials can result in a 5% price difference compared to national standard cables. As we've seen recently, many exposed cable issues stem from problems with auxiliary materials.

3. Short meters in wires and cables. This has always been an issue and is the hardest to detect. It used to be common in BV cables (e.g., 95m, 98m, or 90m cables). Now, with increased inspection items and comprehensive product checks, non-standard cables are resorting to this again. Be aware that a 1-meter reduction from 100 meters yields a 1% profit margin.

4. Thick ends, thin middle. This means the ends of the cable meet national standards, but the middle section does not, saving considerable costs and resulting in a much lower cable price. You can't cut the cable in the middle for testing, so this is how they get away with it.

Currently, the fourth point is the most concerning. As long as the user and cable manufacturer collude, it's impossible to detect. Are we going to dig up the cables to measure them? This explains why cables with the same "national standard" claim can have such vastly different prices.

Recommended News

2024 Social Responsibility Report

2025-03-31

2023 Social Responsibility Report

2024-11-17

2022 Social Responsibility Report

2024-11-17

Youhui Cable Co., Ltd.

Service Hotline:

Email:

youhuixianlan@yeah.net

Production Base:

Jiajiakou Township, Huang'erying Village, Tai'an Road, Jia 6, Ningjin County, Hebei Province